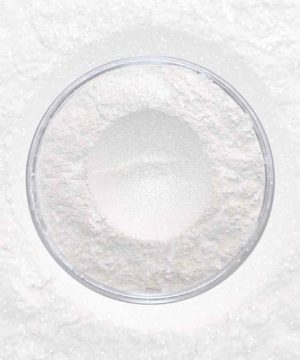

When making cold process as well as melt and pour soap, a spray bottle containing 99% isopropyl alcohol comes in handy. Also known as rubbing alcohol, isopropyl alcohol helps prevent soda ash on cold process soap and helps layers stick together when working with melting and pouring. Soda ash , or sodium carbonate, is a byproduct in it to make from soap this occurs when lye comes into contact with carbon dioxide (CO₂). It leaves a white film on the soap making it look less attractive.

The two most common types of alcohol are isopropyl alcohol and ethyl alcohol. The basic difference between the two is that ethyl alcohol is often used for consumption while isopropyl alcohol is used for topical application. Isopropyl alcohol is not safe for consumption.

Isopropyl alcohol (aka: rubbing alcohol) can be found in various percentages, usually from 60% -99%. The percentage refers to the amount of isopropanol (isopropyl alcohol) per volume. The rest of the formula consists of water. The more dilute rubbing alcohol formulations are often used as a mild topical treatment, while the higher concentrations are often used for cleaning. When making cold process soap or other projects, 99% isopropyl alcohol is recommended.

Wondering how to use isopropyl alcohol in soap making? Air bubbles can sometimes form when working with melting and pouring. Spraying isopropyl alcohol immediately after pouring breaks down these air bubbles and creates a smooth surface. Spraying isopropyl alcohol between melt and cast layers also helps bond the layers. Rubbing alcohol can also be used to disperse oxides and clays for use in melting and casting projects, such as in the Charcoal and Rose Clay Melt and Pour.

For making cold process soap, isopropyl alcohol is great for helping prevent sodium carbonate. Sodium carbonate is formed when unsaponified lye reacts with the carbon monoxide in the air. This reaction creates a white film on the cold process soap. Soda ash is a completely harmless cosmetic problem. Soda ash can be prevented by spraying the top of cold process soap with isopropyl alcohol within 10-15 minutes of pouring your fresh soap.

It’s also useful to have on hand to clean up messy surfaces after creating projects!

Reviews

There are no reviews yet.