The Cinnamon Cocoa Cold Process Soap recipe combines the warm, spicy scent of cinnamon with the rich, chocolatey aroma of cocoa. These delicious-smelling notes come from its high vanilla content, which results in a very dark brown soap. Instead of fighting the discoloration, this Cinnamon Cocoa Cold Process Soap embraces it with a brown and black color palette.

Cinnamon Cocoa Fragrance Oil is only added to the black and brown soap. The base is left unscented so it won’t discolor. Oat oil gives the base a yellow shade so plenty of titanium dioxide is used to create a more neutral shade. Because of the titanium dioxide, this recipe contains a 10% water discount to prevent glycerin rivers.

The water discount also aids in unmolding because this recipe is palm free. When a recipe doesn’t contain palm oil, it’s usually a good idea to add other firm oils or butters for balance. The mango butter, cocoa butter, and babassu oil in this recipe ensure the soap becomes firm. Learn more about palm oil substitutes in cold-process soap here.

How To Make Cinnamon Cocoa Cold Process Soap

Ingredients

- Silicone Loaf Mold

- Hanger Swirl Tool

- 142 g Babassu Oil (15.1%)

- 20 g Castor Oil (2.1%)

- 94 g Cocoa Butter (9.9%)

- 235 g Coconut Oil (25%)

- 28 g Mango Butter (3%)

- 94 g Oat Oil (9.9%)

- 187 g Olive Oil (19.9%)

- 142 g Sunflower Oil (15.1%)

- 136 g Sodium Hydroxide Lye

- 281 g Distilled Water (10% water discount)

- 37 g Cinnamon Cocoa Fragrance Oil

- Isopropyl alcohol

- Black Oxide

- Brown Oxide

- Titanium Dioxide

- Cinnamon Sticks

Instructions

Colorant Prep: Disperse 2 teaspoons of titanium dioxide into 2 tablespoons of a lightweight liquid oil such as sunflower or sweet almond. Disperse 1/2 teaspoon of black oxide into 1/2 tablespoon of lightweight liquid oil. Then, disperse 1 teaspoon of brown oxide into 1 tablespoon of lightweight oil. Use a mini mixer to get rid of clumps.

Optional: To ensure the titanium dioxide blends smoothly into the soap, we recommend micronizing it before dispersing it in oil. Use a coffee grinder to break up any clumps of color and prevent streaks of white from showing in the final soap. We like to use a coffee grinder that has a removable stainless steel mixing area for easy cleaning.

Fragrance Prep: In a glass fragrance oil-safe container, measure out 37 g of Cinnamon Cocoa Fragrance Oil and set aside.

Safety First! Suit up for safe handling practices. That means goggles, gloves, and long sleeves. Make sure kids, pets, other distractions, and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

Step 1: Slowly and carefully add 136 g lye to 280 g distilled water. Gently stir until the lye has fully dissolved. Set it aside to cool. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add 2 teaspoons sodium lactate.

Step 2: Melt and combine 142 g of babassu oil, 20 g of castor oil, 94 g cocoa butter, 235 g coconut oil, 28 g mango butter, 94 g oat oil, 187 g olive oil, and 142 g sunflower oil into a large mixing bowl. Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

Step 3: Split off 200 mL of batter into one container and 300 mL of batter into another container. Add the following colorants to the three containers and whisk in.

- Container A (200 mL): 1/2 teaspoon dispersed black oxide

- Container B (300 mL): 1 teaspoon dispersed brown oxide

- Container C (remaining batter): All dispersed titanium dioxide

Step 4: Add the fragrance oil proportionately to the black and brown soap. Use a whisk to thoroughly mix in the fragrance.

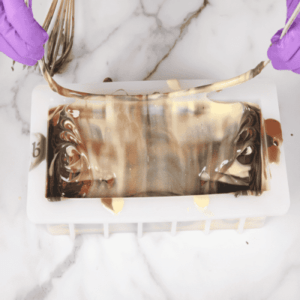

Step 5: Pour a small amount of the white soap into the mold – just enough to cover the bottom. Then, alternate pouring small amounts of the black, brown, and white soap into the mold at varying heights. That helps the soap drop to different areas of the mold rather than sitting on top and creating layers. Don’t worry about being too precise when you’re pouring.

Step 6: Continue pouring the soap into the mold. Save a very small amount of each color for the top.

Step 7: Insert the Hanger Swirl Tool into one side of the mold. Then, use loop-de-loop motions to swirl the soap. There is no right or wrong way to do this. Just keep moving the Hanger Swirl Tool in circular motions. Some loops should be big and some small. Once you’ve swirled the soap about 5-7 times, remove the Hanger Swirl Tool by bringing it up and out on one side of the mold.

Step 8: Pour or plop (depending on your trace – ours was quite thick at this point) lines of the black, white, and brown soap down the length of the mold. Placing the white soap in the center will help create contrast.

Step 9: Insert a dowel or chopstick to swirl the very top of the soap. We used an “S” curve pattern down the length of the mold. Be careful to not over-swirl the soap, or the colors will become muddled.

Step 10: Place cinnamon sticks into one side of the soap at an angle. Place each stick where you’d like the center of the bar to be.

Step 11: Spritz the soap with 99% isopropyl alcohol to help prevent soda ash. Let the soap sit uncovered at room temperature for 2-3 days (depending if you used sodium lactate or not). We found that because this recipe doesn’t contain palm oil, it needed a little bit more time in the mold than usual. Once the mold pulls away from the soap without tearing, unmold it and cut it into bars. Allow them to cure for 4-6 weeks and enjoy.

Reviews

There are no reviews yet.